Introduction

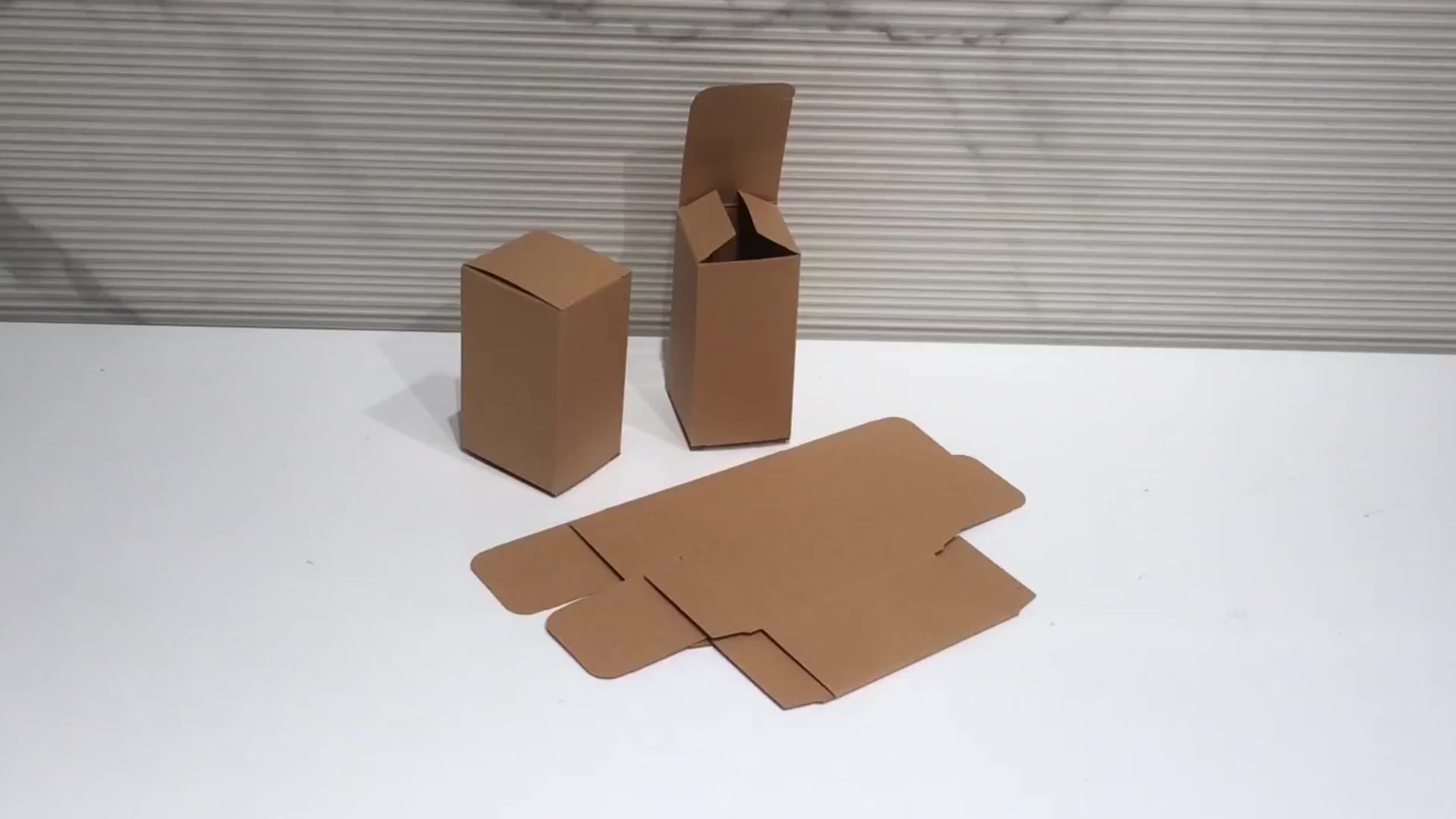

In the fast-paced world of American packaging, efficiency and presentation go hand-in-hand. Seal end auto bottom boxes offer the perfect blend of both, streamlining the packaging process for businesses while elevating the presentation of their products. This article delves into the world of seal end auto bottom boxes in USA, exploring the different materials, customization options, benefits of using them, and tips on finding the ideal partner for your packaging needs.

Unboxing Efficiency: Materials for Seal End Auto Bottom Boxes in USA

The American market offers a variety of materials for your seal end auto bottom boxes, each with its own advantages:

- Cardboard: The most popular choice, cardboard seal end auto bottom boxes in USA are readily available, budget-friendly, and offer surprising sturdiness. They come in recycled varieties for an eco-conscious touch. Consider laminated cardboard for extra moisture resistance.

- Paperboard: Similar to cardboard but with a more premium feel, paperboard seal end auto bottom boxes provide a luxurious presentation. This option is ideal for high-end products or those requiring a more durable structure.

- Kraft Paper: A natural, unbleached option, kraft paper seal end auto bottom boxes in USA add a rustic and eco-friendly aesthetic to your packaging. This aligns with the growing demand for sustainable solutions and can be ideal for organic or handcrafted products.

Additional Considerations:

- Food-Grade Materials: Ensure your chosen material is food-safe, especially for boxes used for packaging food items or products that come into contact with food.

- Window Options: Strategically placed windows on your seal end auto bottom boxes allow customers to catch a glimpse of the product inside, enticing them to purchase. Consider different window shapes or sizes to complement your overall design.

Beyond the Basic Box

The American market thrives on creativity, and seal end auto bottom box customization reflects that. Here are some ways to personalize your boxes and make them stand out:

- Size and Shape: Seal end auto bottom boxes come in various sizes to accommodate different product dimensions. Explore standard rectangular shapes or unique options like square or round boxes for a distinctive touch.

- Printing: From simple logos to full-color artwork depicting your brand story, high-quality printing allows you to personalize your boxes. Consider vibrant colors, clear fonts, and eye-catching designs that resonate with your brand identity.

- Finishing Touches: Foiling, embossing, or spot UV coating can add a touch of luxury and sophistication to your seal end auto bottom boxes in USA. A glossy or matte finish can also elevate the overall look and feel. Consider incorporating custom labels or even ribbons for an extra special touch.

Custom boxes provide tailored packaging solutions that enhance brand identity and offer a unique unboxing experience for customers.

The Power of Efficiency and Presentation

For American businesses, utilizing seal end auto bottom boxes offers a multitude of advantages:

- Faster Assembly: The auto bottom feature allows for quick and easy assembly, streamlining the packaging process and saving valuable time for your employees. This efficiency is particularly beneficial for businesses with high-volume packaging needs.

- Enhanced Presentation: These boxes offer a clean and professional presentation compared to traditional tuck end boxes. The secure seal end closure creates a polished look that elevates the perceived value of your product.

- Durability and Protection: Despite their ease of assembly, seal end auto bottom boxes offer surprising sturdiness. They effectively protect your products during transport, storage, and on retail shelves.

- Versatility: These boxes cater to a wide range of products. From apparel and electronics to food items and cosmetics, seal end auto bottom boxes offer a versatile packaging solution for various industries.

- Sustainability: Many seal end auto bottom box manufacturers in the USA offer eco-friendly materials and printing processes, aligning with the growing demand for sustainable packaging solutions.

Finding Your Perfect Partner: Selecting a Seal End Auto Bottom Box Supplier

With the growing popularity of seal end auto bottom boxes in USA, numerous suppliers offer these solutions in the USA. Here are some key considerations to guide you in selecting the right partner:

- Minimum Order Quantities (MOQs): Wholesale suppliers often have MOQs, which might not be ideal for small businesses. Look for companies with lower MOQs or those that cater to smaller orders.

- Customization Options: Ensure the supplier offers the level of customization you need, including size, printing, material choices, and finishing touches.

- Sustainability Practices: If sustainability is a priority for your brand, choose a supplier that utilizes eco-friendly materials and practices in their manufacturing process.

- Lead Times and Pricing: Get clear quotes outlining lead times for production, the overall cost per box based on your customization choices, and any additional fees.

Conclusion

So ditch the slow assembly and embrace the efficiency of seal end auto bottom boxes in USA. These innovative boxes streamline packaging, elevate product presentation, and offer a sustainable solution. Partnering with the right supplier allows you to create customized boxes that resonate with your brand and leave a lasting impression on American consumers. With faster assembly, a polished look, and versatility, seal end auto bottom boxes are the perfect blend of function and style for your packaging needs.