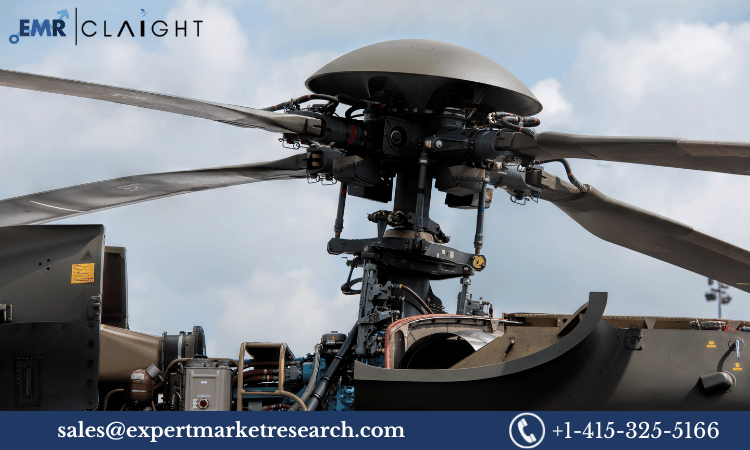

Helicopter Blades Market Outlook

The global helicopter blades market is poised for steady growth over the forecast period from 2024 to 2032, with an expected compound annual growth rate (CAGR) of 4%. This growth trajectory can be attributed to several key factors, including advancements in technology, increasing demand for helicopter services in various sectors, and rising investments in the defense and military sectors.

One of the primary drivers of this market is the continuous innovation and technological advancements in helicopter blade design and materials. Modern helicopter blades are being developed with composite materials that offer superior strength, durability, and reduced weight compared to traditional metal blades. These advancements not only enhance the performance and efficiency of helicopters but also extend the lifespan of the blades, reducing maintenance costs and downtime. As a result, the adoption of advanced composite blades is expected to rise, driving market growth.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/helicopter-blades-market/requestsample

Another significant factor contributing to the market’s expansion is the increasing demand for helicopter services across various industries. The use of helicopters in emergency medical services (EMS), search and rescue operations, and offshore oil and gas exploration has been growing steadily. Helicopters are also crucial in law enforcement, firefighting, and agriculture, further boosting the demand for reliable and high-performance blades. The ability of helicopters to access remote and difficult-to-reach areas makes them indispensable in these applications, thereby fueling the demand for robust and efficient blades.

The defense and military sectors are also expected to play a crucial role in the growth of the helicopter blades market. Governments worldwide are investing heavily in modernizing their military fleets, which includes upgrading existing helicopters and procuring new ones. The increasing focus on enhancing aerial capabilities and ensuring operational readiness is driving the demand for advanced helicopter blades that can withstand rigorous military operations. Additionally, geopolitical tensions and the need for advanced defense systems are prompting countries to bolster their defense budgets, further propelling market growth.

The market’s growth is also supported by the rising investments in research and development (R&D) activities aimed at improving blade performance and efficiency. Manufacturers are focusing on developing innovative blade designs that can reduce noise, enhance fuel efficiency, and improve overall flight performance. Collaborations between industry players and research institutions are fostering the development of next-generation helicopter blades, which are expected to gain significant traction in the coming years.

Read Full Report with Table of Contents@ https://www.expertmarketresearch.com/reports/helicopter-blades-market

However, the market faces certain challenges, including stringent regulatory standards and the high cost of advanced composite materials. Compliance with safety and performance standards set by aviation authorities can be demanding and may require substantial investments in testing and certification processes. Additionally, the initial cost of composite blades can be higher compared to traditional blades, potentially limiting their adoption, particularly among cost-sensitive end-users.

Helicopter Blades Market Segmentation

Breakup by Material Type

- Carbon Composites

- Hybrid Composites

- Fibre-Reinforced Resin (Fibreglass)

Breakup by Blade Location Type

- Main Rotor

- Tail Rotor

Breakup by Distribution Channel

- OEM

- Aftermarket

Breakup by Application

- Military

- Civil

- Others

Breakup by Region

- North America

- United States of America

- Canada

- Europe

- United Kingdom

- Germany

- France

- Italy

- Others

- Asia Pacific

- China

- Japan

- India

- ASEAN

- Australia

- Others

- Latin America

- Brazil

- Argentina

- Mexico

- Others

- Middle East and Africa

- Saudi Arabia

- United Arab Emirates

- Nigeria

- South Africa

- Others

Competitive Landscape

- Van Horn Aviation, LLC

- Carson Helicopters, Inc.

- Kaman Corporation

- Erickson

- Others

Opportunities in the Helicopter Blades Market

- Technological Advancements: The continuous evolution of materials science and engineering technologies presents opportunities for developing more durable, efficient, and lighter helicopter blades. Advanced composite materials can significantly enhance blade performance and longevity.

- Increasing Demand for Helicopters: The rising demand for helicopters in various sectors, including defense, emergency medical services, and corporate transport, drives the need for high-quality helicopter blades. Emerging markets, in particular, are experiencing growth in helicopter procurement.

- Expansion in Commercial Aviation: The commercial aviation sector is expanding, with helicopters being increasingly used for urban air mobility, tourism, and transport services. This expansion creates a consistent demand for helicopter blades.

- Military Modernization Programs: Many countries are investing in the modernization of their military fleets, which includes the acquisition of new helicopters and the upgrading of existing ones. This trend offers significant opportunities for helicopter blade manufacturers.

- Replacement and Maintenance Market: The need for regular maintenance and replacement of helicopter blades ensures a steady demand. As helicopters age, the frequency of blade replacement increases, providing a continuous market for new blades.

Challenges in the Helicopter Blades Market

- High Manufacturing Costs: The production of helicopter blades involves sophisticated technology and high-quality materials, leading to significant manufacturing costs. This can impact pricing and profitability.

- Regulatory Compliance and Certification: Helicopter blades must meet stringent regulatory standards and undergo rigorous certification processes, which can be time-consuming and costly for manufacturers.

- Market Competition: The helicopter blades market is competitive, with numerous established players and new entrants vying for market share. This competition can pressure prices and margins.

- Supply Chain Disruptions: The global supply chain for materials and components used in helicopter blade manufacturing can be susceptible to disruptions due to geopolitical tensions, natural disasters, or pandemics.

- Technological Obsolescence: Rapid advancements in technology can render existing blade designs obsolete, necessitating continuous investment in research and development to stay competitive.

Methods to Deal with Challenges

- Cost Optimization: Manufacturers can focus on optimizing production processes to reduce costs. Implementing lean manufacturing techniques, automating production lines, and sourcing materials more efficiently can help manage expenses.

- Investing in R&D: Continuous investment in research and development is crucial to stay ahead in the market. Developing innovative materials and designs can enhance blade performance and provide a competitive edge. Collaborations with research institutions and universities can also spur innovation.

- Enhancing Regulatory Navigation: Building strong relationships with regulatory bodies and staying updated with changing regulations can streamline the compliance and certification processes. Investing in specialized regulatory compliance teams can ensure adherence to standards without significant delays.

- Diversifying Product Portfolio: To mitigate market competition, manufacturers can diversify their product offerings. This can include developing blades for different types of helicopters or specialized applications such as drones or unmanned aerial vehicles (UAVs).

- Strengthening Supply Chains: Building a robust and resilient supply chain is essential to manage disruptions. This can involve diversifying suppliers, maintaining strategic stockpiles of critical materials, and employing advanced supply chain management technologies to enhance visibility and agility.

- Lifecycle Support and Services: Offering comprehensive lifecycle support, including maintenance, repair, and overhaul (MRO) services, can create additional revenue streams. Providing training and support to operators can also foster long-term customer relationships.

- Market Expansion Strategies: Targeting emerging markets with tailored marketing and sales strategies can unlock new growth opportunities. Demonstrating the value proposition of advanced helicopter blades through case studies and pilot projects can facilitate market penetration.

Read More Trending Reports:

Global Ultra-High Molecular Weight Polyethylene Market: https://www.expertmarketresearch.com/reports/ultra-high-molecular-weight-polyethylene-market

Global Cheese Market: https://www.expertmarketresearch.com/reports/cheese-market

Global Plastic Additives Market: https://www.expertmarketresearch.com/reports/plastic-additives-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Olivia Brown, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/