Metal Forming Machine Tools Market Outlook

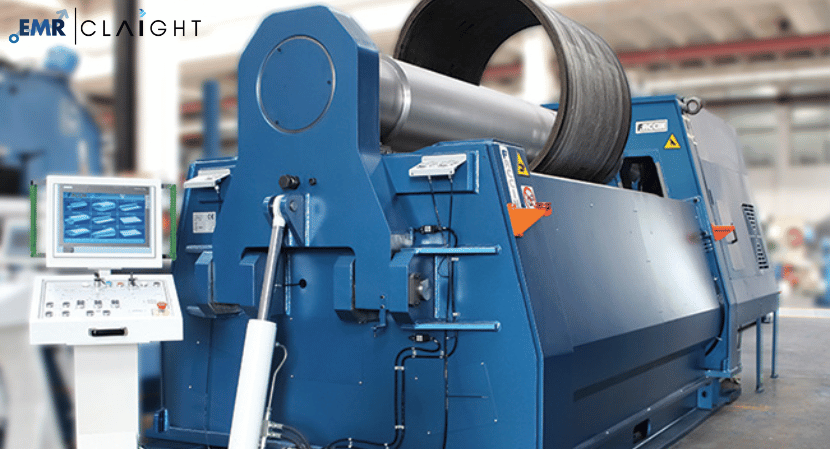

The global metal forming machine tools market is projected to witness substantial growth at a compound annual growth rate (CAGR) of 4% from 2021 to 2026. This upward trajectory is driven by the increasing demand from various end-use industries such as automotive, aerospace, and construction, which require precision-engineered components. Advancements in technology, such as the integration of automation and robotics in manufacturing processes, are also playing a crucial role in enhancing the efficiency and productivity of metal forming machine tools. Additionally, the rise in industrialization, particularly in emerging economies, and the ongoing trend towards lightweight and high-strength materials in manufacturing are further propelling market growth. Companies are increasingly investing in research and development to innovate and expand their product portfolios, thereby meeting the evolving needs of the industry. Moreover, favorable government policies and initiatives aimed at boosting the manufacturing sector are expected to provide significant impetus to the market. As a result, the metal forming machine tools market is poised for robust expansion over the forecast period, catering to the growing demands of a diverse range of industrial applications.

Metal Forming Machine Tools Market Share

Metal Forming Machine Tools Market Segmentations

Metal Forming Machine Tools Market Growth Analysis

The metal forming machine tools market is experiencing significant growth driven by multiple factors across various industries. Key drivers include the increasing demand for precision-engineered components in the automotive, aerospace, and construction sectors. The automotive industry, particularly with its shift towards electric vehicles, requires advanced metal forming technologies to produce lightweight yet durable parts. Similarly, the aerospace sector’s emphasis on innovation and efficiency is boosting the demand for high-precision metal forming tools to manufacture critical components with stringent quality standards.

Technological advancements are also playing a crucial role in the market’s expansion. The integration of automation and robotics in metal forming processes is enhancing productivity and operational efficiency, making these tools more attractive to manufacturers. The rise of Industry 4.0 and smart manufacturing trends are fostering the adoption of sophisticated metal forming technologies, as companies leverage digitalization and data analytics to optimize their production processes. These technological innovations are expected to drive further adoption of advanced metal forming machine tools across various sectors.

Emerging economies are contributing significantly to the growth of the metal forming machine tools market. Rapid industrialization and supportive government policies aimed at bolstering the manufacturing sector are key factors driving market expansion in these regions. Investments in infrastructure development and the establishment of new manufacturing facilities are increasing the demand for metal forming machine tools. Additionally, the trend of reshoring manufacturing activities to mitigate supply chain disruptions is creating new growth opportunities for market players. These factors collectively indicate a positive growth trajectory for the global metal forming machine tools market in the coming years.

Metal Forming Machine Tools Market Trends and Drivers

1. Automation and Robotics Integration: The incorporation of automation and robotics into metal forming processes is a significant trend. Automated systems and robotic arms enhance precision, speed, and efficiency, reducing human error and increasing production rates. This trend is particularly prominent in high-volume manufacturing sectors like automotive and aerospace.

2. Industry 4.0 and Smart Manufacturing: The advent of Industry 4.0 is revolutionizing the metal forming machine tools market. Smart manufacturing involves the use of IoT, AI, and data analytics to optimize production processes. Real-time monitoring, predictive maintenance, and data-driven decision-making are becoming standard practices, improving overall operational efficiency and reducing downtime.

3. Lightweight Materials: The demand for lightweight materials, especially in the automotive and aerospace industries, is driving the development of advanced metal forming technologies. These materials require specialized forming processes to ensure they meet the necessary strength and durability standards without adding excess weight.

4. Customization and Flexibility: There is a growing trend towards customization and flexibility in manufacturing. Metal forming machine tools are being designed to handle small batch sizes and customized products efficiently. This trend caters to the increasing demand for personalized products and just-in-time manufacturing.

Drivers:

1. Growing Automotive Industry: The automotive industry’s expansion, especially with the shift towards electric vehicles, is a major driver. The need for new, lightweight, and high-strength components is pushing the demand for advanced metal forming machine tools.

2. Advancements in Aerospace: The aerospace industry’s growth, driven by increased air travel and advancements in aerospace technology, is boosting the demand for high-precision metal forming tools. The production of complex and high-quality aerospace components relies heavily on these tools.

3. Infrastructure Development: Infrastructure projects worldwide, particularly in emerging economies, are driving the demand for metal forming machine tools. The construction of new buildings, bridges, and other structures requires a variety of metal-formed components.

4. Reshoring of Manufacturing: The trend of reshoring manufacturing activities back to domestic markets to ensure supply chain resilience and reduce dependency on foreign suppliers is creating new opportunities for the metal forming machine tools market. This trend is particularly strong in regions like North America and Europe.

5. Environmental and Regulatory Pressures: Environmental regulations and the push for sustainable manufacturing practices are driving the adoption of energy-efficient and environmentally friendly metal forming technologies. Companies are increasingly investing in tools that reduce waste and energy consumption.

6. Technological Innovations: Continuous technological advancements in metal forming machine tools, such as the development of more efficient CNC machines and innovative forming techniques, are propelling market growth. These innovations are enhancing the capabilities and applications of metal forming tools across various industries.

Read More Reports:

Top 10 Companies with an Established Presence in the Global Eyewear Market

Global Apparel, Accessories, and Footwear Market

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com