The construction industry in India is experiencing rapid growth, and with it comes an increasing demand for sustainable and cost-effective building materials. Fly ash bricks have emerged as a popular alternative to traditional clay bricks, offering superior strength, durability, and environmental benefits. To meet this growing demand, manufacturers are turning to advanced fly ash brick making machine in India. In this comprehensive guide, we’ll explore the world of high-quality fly ash brick making machines available in India, their benefits, and how they’re revolutionizing the construction industry.

The Rise of Fly Ash Bricks

Before delving into the machines that produce them, it’s essential to understand why fly ash bricks have gained such popularity in recent years:

1. Environmental Sustainability: Fly ash bricks utilize waste materials from thermal power plants, reducing the environmental impact of brick production.

2. Cost-Effectiveness: These bricks are often more economical to produce than traditional clay bricks.

3. Strength and Durability: Fly ash bricks exhibit excellent compressive strength and resistance to weathering.

4. Consistency: Machine-made fly ash bricks offer uniform size and quality, ensuring better construction outcomes.

Advanced Fly Ash Brick Making Machines

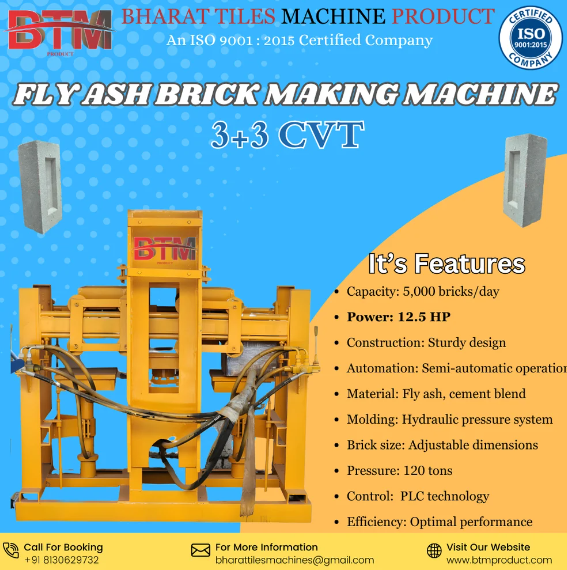

BTM Product, a leading manufacturer in India, offers state-of-the-art fly ash brick making machines that cater to various production needs. These machines are designed to produce high-quality bricks efficiently and consistently. Let’s explore the key features and benefits of these advanced machines:

1. Automated Production Process

Modern fly ash brick making machines employ sophisticated automation technologies to streamline the production process. This automation ensures:

– Consistent mix ratios

– Uniform compression

– Precise cutting and shaping

– Reduced manual labor and human error

2. High Production Capacity

Fly ash brick making machines available in India come in various capacities to suit different production requirements. Some high-end models can produce up to 20,000 bricks per day, making them ideal for large-scale construction projects.

3. Versatility in Brick Types

Advanced machines offer the flexibility to produce different types of bricks, including:

– Standard fly ash bricks

– Hollow blocks

– Solid blocks

– Interlocking bricks

This versatility allows manufacturers to cater to diverse market demands using a single machine.

4. Energy Efficiency

Modern fly ash brick making machines are designed with energy efficiency in mind. They incorporate features such as:

– Variable frequency drives

– Energy-efficient motors

– Optimized hydraulic systems

These features not only reduce energy consumption but also lower production costs.

5. Quality Control Mechanisms

To ensure consistently high-quality output, advanced machines are equipped with various quality control mechanisms, including:

– Pressure sensors for uniform compression

– Moisture control systems

– Automatic brick rejection systems for defective units

6. User-Friendly Interface

Many modern fly ash brick making machines feature intuitive control panels and touchscreen interfaces, making operation and monitoring easy for workers of various skill levels.

Complementary Machines: Expanding Your Production Line

While fly ash brick making machines are the cornerstone of brick production, manufacturers often expand their product lines to include other construction materials. Two popular additions are interlocking tiles making machine in India and paver block making machine in India.

Interlocking Tiles Making Machines

Interlocking tiles have gained popularity for their ease of installation and aesthetic appeal. BTM Product offers advanced interlocking tiles making machine in India that complement their fly ash brick making machine in India. These machines produce high-quality interlocking tiles suitable for various applications, including:

– Walkways

– Driveways

– Patios

– Indoor flooring

The interlocking tiles making machine in India offered by BTM Product feature:

– Multiple mold options for various designs

– High production capacity

– Precision cutting and shaping

– Durable construction for long-term use

Paver Block Making Machines

Paver blocks are another essential product in the construction industry, widely used for outdoor flooring and landscaping. BTM Product’s range of paver block making machine in India are designed to produce high-quality, durable paver blocks efficiently. These machines offer:

– Versatility in block shapes and sizes

– High compressive strength for the finished products

– Efficient production process

– Easy maintenance and operation

By incorporating both interlocking tiles making machine in India and paver block making machine in India alongside fly ash brick making machines, manufacturers can diversify their product offerings and cater to a broader market.

Choosing the Right Fly Ash Brick Making Machine

When selecting a fly ash brick making machine in India, consider the following factors:

1. Production Capacity: Determine your required daily output and choose a machine that meets or exceeds this capacity.

2. Brick Specifications: Ensure the machine can produce bricks that meet the required size, shape, and strength specifications for your target market.

3. Automation Level: Consider the level of automation that best suits your production needs and workforce skills.

4. Energy Efficiency: Look for machines with energy-saving features to reduce long-term operational costs.

5. Maintenance Requirements: Choose machines that are easy to maintain and have readily available spare parts.

6. Manufacturer Reputation: Opt for reputable manufacturers like BTM Product, known for their quality and after-sales support.

7. Cost and ROI: Evaluate the initial investment against the expected return on investment based on your production goals and market demand.

The Future of Brick Making in India

As the construction industry in India continues to evolve, the demand for high-quality, sustainable building materials is expected to grow. Fly ash brick making machine in India, along with complementary products like interlocking tiles making machine in India and paver block making machine in India, are poised to play a crucial role in meeting this demand.

Manufacturers like BTM Product are at the forefront of this revolution, continually innovating and improving their machines to meet the changing needs of the industry. As technology advances, we can expect to see even more efficient, versatile, and environmentally friendly brick making machines in the future.

Conclusion

High-quality fly ash brick making machines available in India are transforming the construction industry by providing a sustainable, cost-effective alternative to traditional brick production methods. These advanced machines, offered by reputable manufacturers like BTM Product, combine automation, efficiency, and quality control to produce superior bricks that meet the demanding standards of modern construction.

By investing in a fly ash brick making machine in India, manufacturers can position themselves at the forefront of the sustainable construction movement. Moreover, by expanding their product lines to include interlocking tiles making machines in India and paver block making machine in India, they can offer a comprehensive range of construction materials to meet diverse market needs.

As the industry continues to evolve, the importance of choosing the right equipment cannot be overstated. By carefully considering factors such as production capacity, energy efficiency, and manufacturer reputation, businesses can make informed decisions that will drive their success in the competitive construction materials market.

With the right fly ash brick making machine and a commitment to quality and innovation, manufacturers in India can contribute to a more sustainable, efficient, and prosperous construction industry for years to come.