Choosing the right fly ash brick making machine in India can be a crucial decision for your construction or manufacturing business. The right machine not only increases efficiency but also ensures the production of high-quality bricks that meet industry standards. With various options available in the market, it can be overwhelming to make the right choice. This guide will help you understand the essential factors to consider and how to find the best fly ash brick making machine in India for your needs.

Understanding Fly Ash Brick Making Machines

Fly ash bricks are made using fly ash, lime, gypsum, and sand. These bricks are known for their durability, strength, and eco-friendly nature. A fly ash brick making machine automates the process of mixing these materials and forming bricks, saving time and labor costs. When choosing such a machine, it’s essential to consider factors such as production capacity, automation level, and the type of bricks you want to produce.

Key Factors to Consider

1. Production Capacity

One of the first factors to consider when choosing a fly ash brick making machine in India is the production capacity. Determine how many bricks you need to produce daily, weekly, or monthly. Machines come in various capacities, ranging from small-scale units producing a few hundred bricks per day to large industrial machines capable of producing thousands of bricks daily. Make sure to choose a machine that meets your production needs without compromising quality.

2. Automation Level

Fly ash brick making machines come with different levels of automation. You can find manual, semi-automatic, and fully automatic machines. Manual machines require significant human intervention, whereas fully automatic machines handle the entire process, from mixing raw materials to forming and curing bricks. Semi-automatic machines strike a balance between the two. Consider your budget and labor availability when choosing the automation level.

3. Quality and Durability

Investing in a high-quality and durable machine is crucial for long-term success. Look for machines made from robust materials that can withstand harsh working conditions. Check for features such as corrosion resistance and wear-resistant components. Reading reviews and seeking recommendations from other users can provide insights into the machine’s performance and longevity.

4. Technology and Features

Modern fly ash brick making machines come with advanced technology and features that enhance efficiency and productivity. Look for machines with features such as programmable logic controllers (PLCs), hydraulic systems, and automatic raw material feeding systems. These features can significantly reduce downtime and increase the quality of the bricks produced.

Types of Fly Ash Brick Making Machines

There are several types of fly ash brick making machines available in the market. Each type has its own set of advantages and is suitable for different production needs.

1. Hydraulic Brick Making Machines

Hydraulic brick making machines use hydraulic pressure to form bricks. These machines are known for their high production capacity and consistent brick quality. They are suitable for large-scale production and can produce various brick types, including interlocking bricks, paver blocks, and standard fly ash bricks.

2. Mobile Brick Making Machines

Mobile brick making machines are portable and can be moved to different locations. These machines are ideal for on-site production, reducing transportation costs and ensuring timely delivery of bricks. They are suitable for small to medium-scale production.

3. Automatic Brick Making Machines

Automatic brick making machines are fully automated and require minimal human intervention. These machines handle the entire process, from mixing raw materials to curing bricks. They are suitable for large-scale production and ensure high efficiency and consistent quality.

Choosing the Right Manufacturer

Selecting a reliable manufacturer is crucial when purchasing a fly ash brick making machine in India. A reputable manufacturer will provide high-quality machines, excellent after-sales service, and technical support. Consider the following factors when choosing a manufacturer:

1. Reputation and Experience

Look for manufacturers with a strong reputation and years of experience in the industry. A well-established manufacturer is more likely to provide reliable and durable machines. Check for customer reviews, testimonials, and case studies to gauge the manufacturer’s reputation.

2. After-Sales Service and Support

After-sales service and support are crucial for the smooth operation of your machine. Ensure that the manufacturer provides prompt and efficient after-sales service, including technical support, spare parts availability, and maintenance services. A good manufacturer will offer training for your staff to ensure the machine is operated correctly.

3. Customization Options

Every business has unique requirements, and a good manufacturer will offer customization options to meet your specific needs. Whether it’s adjusting the production capacity, incorporating additional features, or designing a machine to produce specific brick types, customization can enhance the machine’s efficiency and suitability for your business.

Cost Considerations

The cost of a fly ash brick making machine in India can vary significantly based on factors such as production capacity, automation level, and additional features. While it’s essential to stay within your budget, avoid compromising on quality for the sake of cost. Investing in a high-quality machine may have a higher upfront cost but can save you money in the long run by reducing maintenance costs and increasing productivity.

Environmental Considerations

Fly ash brick making machines are known for their eco-friendly nature as they utilize fly ash, a waste product from thermal power plants. When choosing a machine, consider its environmental impact. Look for machines that minimize waste, reduce energy consumption, and produce low-emission bricks. Opting for an environmentally friendly machine not only benefits the environment but can also enhance your company’s reputation.

Interlocking Tiles Making Machine in India

In addition to fly ash brick making machines, many manufacturers offer interlocking tiles making machines in India. These machines are used to produce interlocking tiles, which are popular for pavements, driveways, and walkways due to their durability and aesthetic appeal. When choosing an interlocking tiles making machine, consider factors such as production capacity, automation level, and the types of tiles you want to produce.

Paver Block Making Machine in India

Paver blocks are widely used in landscaping, roads, and outdoor flooring. A paver block making machine in India is designed to produce high-quality paver blocks efficiently. These machines come in various types, including hydraulic, automatic, and mobile paver block making machines. Consider your production needs and budget when choosing a paver block making machine in India.

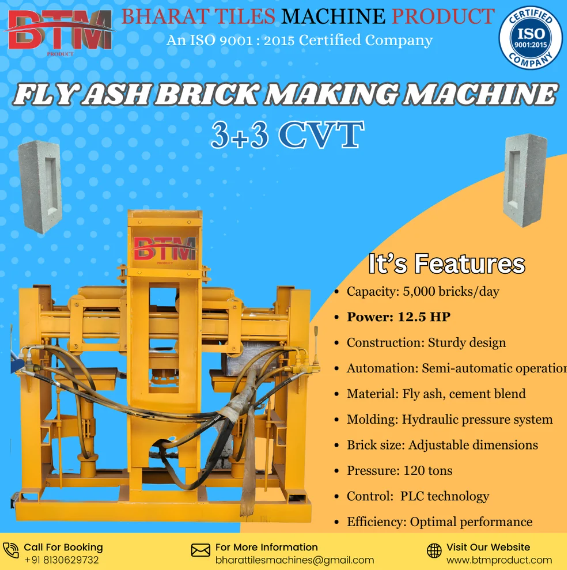

BTM Product: A Trusted Name

When it comes to choosing the right fly ash brick making machine in India, BTM Product is a trusted name in the industry. With years of experience and a reputation for delivering high-quality machines, BTM Product offers a range of fly ash brick making machines, interlocking tiles making machine in India, and paver block making machines in India. Their machines are known for their durability, advanced technology, and excellent after-sales service.

Conclusion

Choosing the right fly ash brick making machine in India is a significant investment that can impact the success of your business. By considering factors such as production capacity, automation level, quality, and manufacturer reputation, you can make an informed decision that meets your specific needs. Whether you are looking for a fly ash brick making machine, an interlocking tiles making machine in India, or a paver block making machine in India, BTM Product offers reliable and efficient solutions to help you achieve your production goals.

Investing in the right machine not only enhances your production efficiency but also ensures the production of high-quality bricks that meet industry standards. With the right fly ash brick making machine in India, you can contribute to sustainable construction practices and the development of eco-friendly infrastructure.