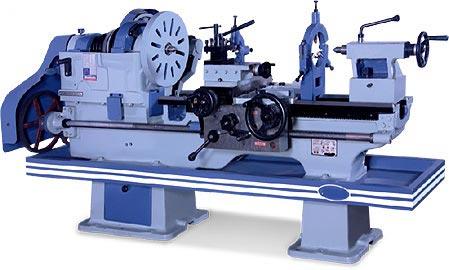

India has long been a hub for industrial innovation, and when it comes to precision tools Lathe machine in India are at the heart of the country’s manufacturing landscape. Known for their versatility and reliability, lathe machines are essential in the production of everything from intricate metal components to robust industrial machinery. This blog delves into the importance of lathe machines in India’s thriving metalworking sector and explores how they are shaping the future of the industry.

The Rise of Lathe Machines in India

India’s journey with lathe machines began decades ago when traditional methods of metal shaping were replaced with mechanized solutions. Today machines in India are recognized globally for producing high-quality equipment that meets diverse industrial needs.

The country has evolved into a significant player in the global lathe machine market, offering everything from manual to CNC (Computer Numerical Control) machines. These machines cater to industries like automotive, aerospace, construction, and energy, making India a preferred destination for both domestic and international buyers.

Why Lathe Machines Are Indispensable in Metalworking

Lathe machines are the backbone of metalworking. Their ability to perform a wide array of tasks, such as cutting, drilling, sanding, and threading, makes them invaluable to manufacturers. Here are some reasons why lathe machines are indispensable:

- Precision and Efficiency

Whether creating intricate designs or producing identical parts in bulk, lathe machines deliver unparalleled precision. This precision is critical in industries like aerospace and automotive, where even the smallest errors can have significant consequences. - Versatility

Lathe machines can work with various materials, including metals, plastics, and wood. This versatility ensures their widespread application across multiple industries. - Cost-Effective Production

By automating repetitive tasks, lathe machines significantly reduce production time and labor costs, providing manufacturers with a competitive edge.

Types of Lathe Machines Popular in India

The demand for lathe machines in India is driven by their wide-ranging applications. Here’s a look at some of the most popular types:

1. Manual Lathe Machines

Perfect for small-scale industries and workshops, manual lathes are cost-effective and easy to operate. These machines are ideal for tasks that require high precision but low automation.

2. CNC Lathe Machines

CNC lathes are at the forefront of modern manufacturing. These machines use computer programming to execute highly accurate and complex tasks, making them indispensable for mass production.

3. Heavy-duty lathe Machines

Designed to handle large and heavy materials, these machines are commonly used in industries like shipbuilding and heavy engineering.

4. Light-Duty Lathe Machines

Compact and efficient, light-duty lathes are ideal for small workshops and educational institutions.

Advancements in Lathe Machine Technology

The integration of cutting-edge technology has revolutionized lathe machines, making them smarter, faster, and more reliable. Here are some advancements shaping the future of lathe machines in India:

- IoT Integration

Internet of Things (IoT) technology allows real-time monitoring and remote operation of lathe machines. This ensures better efficiency and predictive maintenance. - AI and Machine Learning

AI-powered lathe machines can self-optimize their operations, reducing errors and enhancing productivity. - Energy-Efficient Designs

Newer models focus on reducing energy consumption, aligning with India’s sustainability goals. - Enhanced Safety Features

Advanced safety mechanisms, such as automatic shut-off and operator detection systems, are becoming standard features.

The Role of Indian Manufacturers in Global Markets

Indian manufacturers are gaining global recognition for their commitment to quality and innovation. Brands such as Lathe Machines in India: Shaping the Future of Metalworking are at the forefront of this revolution, offering solutions that cater to both traditional and modern manufacturing needs.

Competitive Advantages of Indian Lathe Machines:

- Cost-Effectiveness: Indian manufacturers provide high-quality machines at competitive prices, making them an attractive choice for buyers worldwide.

- Customization: Many Indian manufacturers offer tailored solutions to meet specific industrial requirements.

- After-Sales Support: Excellent customer service and readily available spare parts ensure seamless operation of the machines.

Challenges and Opportunities

While the future looks promising, the Indian lathe machine industry faces challenges such as rising raw material costs and increasing global competition. However, these challenges also present growth opportunities:

- Focus on Exports

Expanding into international markets can drive growth, especially in regions like Africa and Southeast Asia, where demand for industrial machinery is rising. - Innovation and R&D

Investing in research and development will help Indian manufacturers stay ahead of the curve and develop next-generation lathe machines. - Skill Development

Training the workforce to operate advanced lathe machines will ensure that India remains a leader in the global market.

Shaping the Future of Metalworking

The role of lathe machines in India’s industrial growth cannot be overstated. As the country continues to invest in infrastructure and manufacturing, the demand for efficient and innovative lathe machines will only increase. Companies like Lathe Machines in India: Shaping the Future of Metalworking are not just meeting this demand but are also setting new benchmarks for quality and innovation.

By embracing advanced technology, focusing on sustainability, and addressing global market needs, India is poised to shape the future of metalworking. Whether you’re a small-scale entrepreneur or a large-scale manufacturer, investing in high-quality lathe machines is a step toward enhanced productivity and long-term success.

Partner with the Best in the Industry

If you’re looking to elevate your manufacturing processes, partnering with a reliable lathe machine provider is crucial. Lathe Machines in India: Shaping the Future of Metalworking stands out as a trusted name in the industry, offering a wide range of solutions tailored to your needs.

With a commitment to quality, innovation, and customer satisfaction, the company ensures that you get the best value for your investment. Discover the difference that high-quality lathe machines can make in your operations—because the future of metalworking starts here.