As the mattress industry continues to evolve, manufacturers are turning to automation to improve efficiency and maintain high-quality standards. One of the most essential innovations in this sector is the automatic tape edge machine. This advanced technology not only enhances productivity but also ensures consistency in mattress finishing. Here are five key ways tape edge machines can transform your mattress production process.

1. Increase Production Speed with Automation

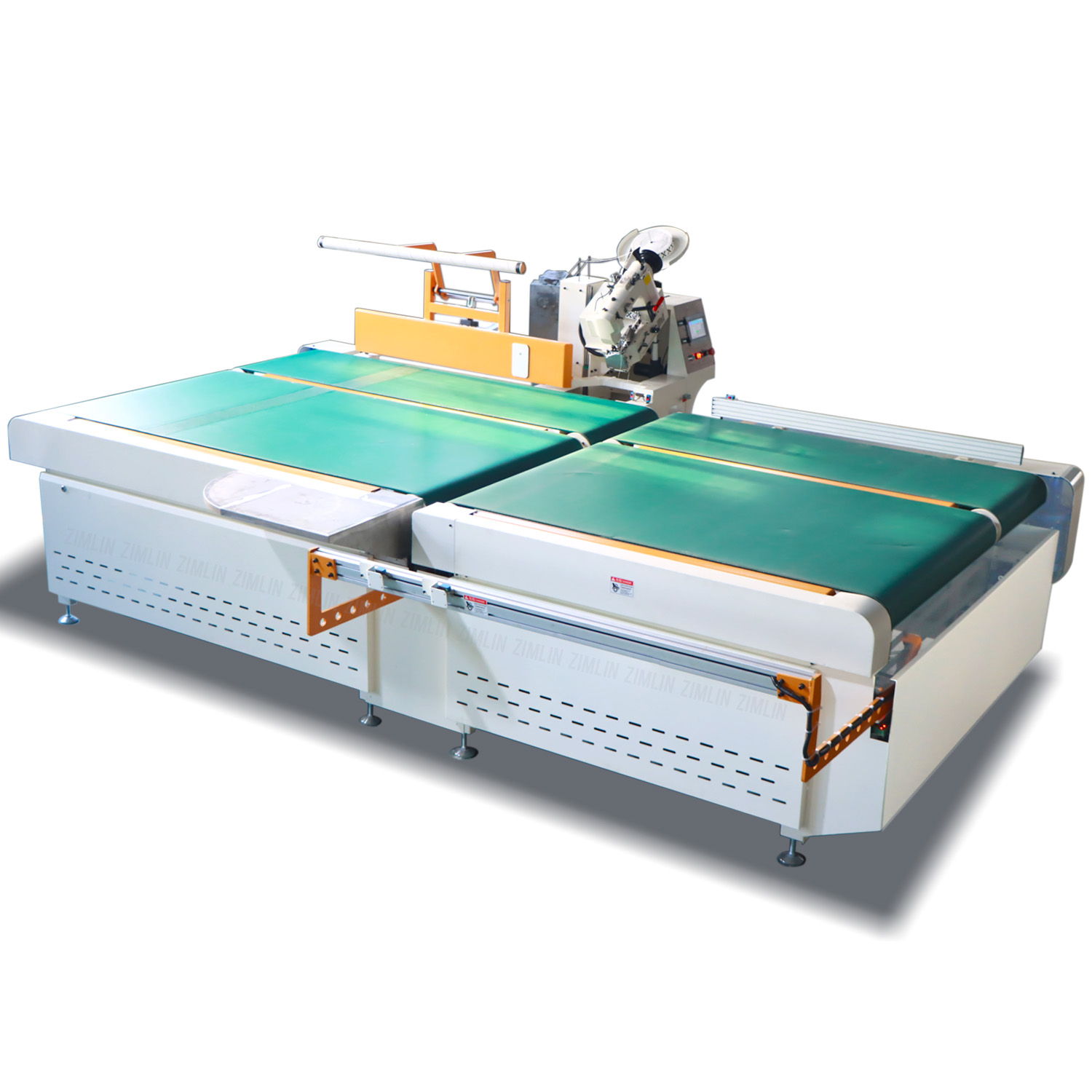

Manual sewing processes can be slow and labor-intensive. By using automatic tape edge machines, manufacturers can significantly reduce production time while maintaining precision. These machines automate the stitching of mattress edges, allowing for faster and smoother operations. This means more output in less time, helping businesses meet growing market demands.

2. Improve Stitching Accuracy and Quality

One major challenge in mattress manufacturing is ensuring uniform stitching around the edges. Traditional methods often result in inconsistencies due to human error. However, with an automatic mattress sewing machine, precise stitching is achieved consistently. This results in durable, professional-quality finishes that enhance the overall appeal of the product. Explore this machine

3. Reduce Labor Costs and Minimize Manual Work

Labor shortages and rising wages are pushing manufacturers to find cost-effective solutions. Investing in automatic tape edge machines reduces the need for manual labor while increasing output. Operators can focus on overseeing production instead of performing repetitive sewing tasks, leading to better resource allocation and cost savings.

4. Adapt to Different Mattress Designs with Ease

Today’s market demands a variety of mattress types, from memory foam to hybrid models. Modern tape edge machines are designed with adjustable settings that accommodate different mattress thicknesses and materials. With features like auto-flipping and programmable controls, manufacturers can quickly switch between mattress designs without disrupting workflow.

5. Partner with a Reliable Manufacturer for Long-Term Success

To fully benefit from automation, it’s essential to choose high-quality equipment from a trusted supplier. ZIMLIN Mattress Machinery specializes in advanced mattress production equipment, including pocket spring machine, mattress packing machine, foam cutting machine, and pillow packing machine. With years of expertise in the industry, ZIMLIN provides durable and high-performance solutions to optimize manufacturing processes.

Final Thoughts

As competition in the mattress industry intensifies, integrating automatic tape edge machines into your production line can give you a significant edge. These machines enhance efficiency, reduce costs, and ensure superior product quality, making them an essential investment for modern mattress manufacturers.