Refining Excellence: State-of-the-Art Gold Machines

Throughout history, gold has held a captivating allure. Its enduring beauty, unwavering value, and diverse industrial applications solidify its place as a precious commodity.

But in its natural state, or even in the form of scrap jewelry, gold isn’t pure. It’s often alloyed with other metals, diminishing its worth and versatility.

Here’s where the marvels of gold refinery machines come into play. These engineering marvels separate gold from unwanted elements, transforming it into a pure and valuable asset.

The Alchemy of Separation: Unveiling the Magic of Gold Refining

Gold refining machines are the unsung heroes of the precious metals industry. They act as the bridge between raw material and refined treasure. Understanding the process allows us to appreciate the intricate dance of chemistry and engineering at play.

-

Dissolution: Breaking Down the Alloy – The journey begins with the gold-containing material (scrap jewelry, electronic components, etc.) meeting its nemesis – a carefully chosen chemical solution. This solution plays a crucial role, dissolving the unwanted metals and leaving the gold relatively untouched. The specific concoction depends on the type of impurities present. For instance, aqua regia, a potent mixture of nitric and hydrochloric acid, is commonly used for gold due to its ability to dissolve most other metals. However, alternative solutions like cyanide leaching are employed for specific applications.

-

Filtration: Separating the Precious from the Mundane – Once the dissolution magic has taken effect, the solution undergoes filtration. Imagine a meticulous sifting process. Here, specialized filters trap the gold particles, leaving behind the dissolved impurities in the filtrate (the leftover liquid). This filtrate may undergo further processing to recover any remaining precious metals or be disposed of responsibly, adhering to strict environmental regulations.

-

Precipitation: Isolating the Golden Prize – With the gold particles separated, the next step involves isolating them from the remaining solution. This is where techniques like precipitation come into play. Imagine adding a chemical “magnet” that attracts the gold particles, causing them to clump together and solidify out of the solution. This “magnet” could be another carefully chosen chemical that reacts specifically with gold. Once precipitated, these gold “clumps” are then separated from the remaining liquid.

-

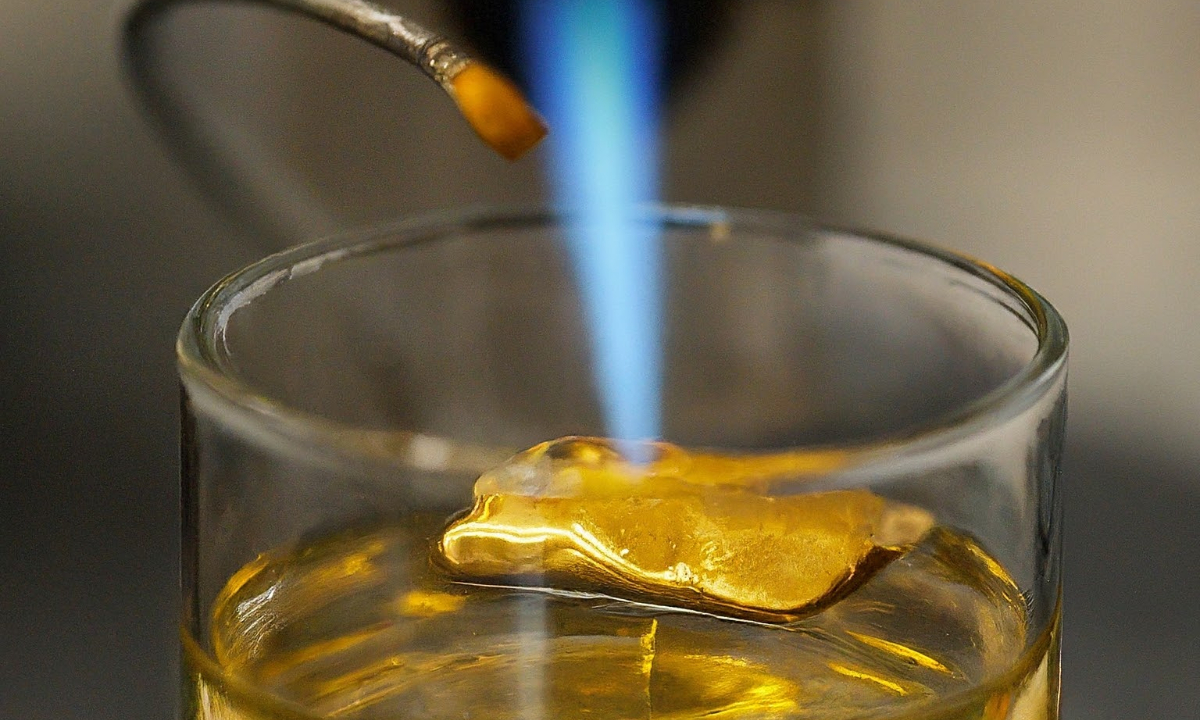

Melting: Forging the Final Form – The isolated gold, though separated, isn’t quite ready for its grand entrance. It still needs to be transformed into a usable form. This is achieved by melting the gold in a furnace at extremely high temperatures. The intense heat further removes any remaining impurities, leaving behind pure gold. The molten gold can then be cast into ingots, bars, or other desired shapes, ready to embark on its next adventure.

A Journey Through Time: From Batch Processing to Automated Excellence

Traditionally, gold refining was a meticulous, hands-on process. Skilled technicians meticulously monitored every stage, ensuring optimal results.

However, the landscape has dramatically shifted, ushering in an era of automation and efficiency with the introduction of modern gold refining machines.

-

Embracing Automation: Consistency and Control – Today’s machines are equipped with advanced control systems that meticulously manage the entire refining process. Imagine a conductor overseeing an orchestra – these control systems precisely orchestrate every step, from the precise dosing of chemicals to the meticulous control of furnace temperatures. This level of automation minimizes human error and ensures consistent, high-quality results across every batch.

-

Scaling Up: Processing Power for Increased Productivity – Modern machines boast significantly larger capacities compared to their traditional counterparts. This translates to the ability to process substantial quantities of gold-bearing materials in a single cycle. Imagine a single machine capable of refining an entire vault of scrap jewelry in a fraction of the time it would take traditional methods. This not only boosts overall productivity for refiners but also reduces processing costs.

-

Environmental Responsibility: A Sustainable Approach – Modern machines prioritize environmental responsibility. Advanced fume control systems capture and neutralize harmful emissions generated during the refining process. This ensures the safety of workers and protects the surrounding environment. Additionally, refiners are increasingly exploring methods to recycle process solutions, minimizing waste and further reducing the environmental footprint.

Beyond the Golden Touch: Refining a Spectrum of Precious Metals

While gold refining is a prominent application, these versatile machines are adept at handling a broader range of precious metals. By tweaking the process slightly, they can be used to refine:

-

Silver: A Shining Companion – Silver, another highly sought-after precious metal, can be refined using similar principles as gold. The specific chemicals used in the dissolution stage may differ depending on the impurities present. For instance, a solution of sodium cyanide and lime is commonly used for silver due to its effectiveness in dissolving copper, a common impurity in silver ores.

-

Platinum Group Metals (PGMs): Industrial Catalysts – This group encompasses platinum, palladium, rhodium, and others. These PGMs play a critical role in various industrial applications, most notably as catalysts in catalytic converters that help reduce harmful emissions from vehicles. Gold refining machines, adapted for PGMs, become instrumental in recovering these valuable metals from spent catalysts. The specific process for PGMs involves:

High-Temperature Techniques: Due to the high melting points of these metals, high-temperature techniques like fire assay or induction melting may be employed.

Fire assay involves a high-temperature fusion process with specific fluxes to separate the PGMs from the surrounding material. Induction melting utilizes electromagnetic fields to induce heat within the material, facilitating separation.

Chemical Separation Techniques: Once the PGMs are concentrated, further separation techniques like precipitation or solvent extraction come into play. These techniques target the specific chemical properties of each PGM, allowing for their individual recovery.

The Evolving Landscape: A Glimpse into the Future of Gold Refining Machines

The future of gold refining machines is bright, driven by innovation and a focus on efficiency and sustainability. Here are some exciting trends to watch:

-

Continuous Processing: Streamlining the Refining Journey – Batch processing, while efficient, has limitations. The future might see the rise of continuous processing machines. Imagine a continuous flow of gold-bearing material being processed uninterruptedly, significantly boosting overall throughput and production. These machines would eliminate the need to stop and start for each batch, leading to even greater efficiency and productivity.

-

Embracing Green Technology: A Sustainable Future for Gold – Sustainability is a growing concern. The focus will continue to drive the development of eco-friendly gold refining machines. This could involve the exploration of:

- Non-Toxic Chemicals: Replacing traditional, potentially harmful chemicals with safer alternatives. Research into new, environmentally friendly leaching and precipitation agents is ongoing.

- Process Solution Recycling: Developing closed-loop systems that recycle and reuse process solutions during the refining process. This would minimize waste generation and reduce the environmental impact.

- Alternative Energy Sources: Exploring more sustainable energy sources to power the machines. This could involve the use of solar, wind, or geothermal energy to reduce reliance on fossil fuels.

-

Advanced Sensors and Controls: Optimizing Every Step – The integration of advanced sensors and real-time monitoring systems will further optimize the refining process. Imagine sensors continuously monitoring factors like chemical concentrations, temperatures, and pressure throughout the process. This data can be used to make real-time adjustments, ensuring the highest possible yield of pure gold and minimizing waste. Additionally, these systems can be used for predictive maintenance, identifying potential issues before they occur and minimizing downtime.

Final Remarks: Gold Refining Machines – A Pillar of the Precious Metals Industry

Gold refining machines are the workhorses of the precious metals refinery industry. They transform raw materials into the pure gold that underpins economies, fuels innovation, and continues to captivate us with its enduring beauty.

As technology continues to evolve, we can expect even more efficient, sustainable, and sophisticated gold refining machines in the years to come.

These advancements will not only revolutionize the gold refining process but will also ensure the continued responsible and environmentally conscious recovery of this precious metal.