Layer Pads Market Outlook

Layer Pads Market Share

Layer Pads Market Segmentations

The global layer pads market has experienced significant growth in recent years, driven by the increasing demand for efficient and reliable packaging solutions across various industries. The market growth is primarily attributed to the rising e-commerce sector, where robust packaging is essential to ensure the safe delivery of goods. Layer pads are particularly valuable in this context as they provide stability and protection for stacked products during transit, reducing the risk of damage.

Key Growth Drivers:

- E-Commerce Boom: The exponential growth of the e-commerce industry has significantly increased the demand for secure and efficient packaging solutions. Layer pads help in maintaining product integrity during shipping, making them indispensable for online retailers.

- Global Supply Chain Expansion: As supply chains become more global and complex, the need for reliable packaging solutions like layer pads has grown. They are crucial for protecting goods during long-haul transportation and in diverse climatic conditions.

- Sustainability Trends: With a growing emphasis on sustainable packaging, there has been a shift towards eco-friendly materials. Paperboard layer pads, in particular, have gained traction due to their recyclability and lower environmental impact compared to plastic alternatives.

- Industry-Specific Demands: Various industries, including food and beverages, electronics, and chemicals, have specific packaging requirements that drive the demand for layer pads. For instance, the food and beverage sector relies on these pads to prevent product contamination and damage during storage and transportation.

Market Segmentation and Customization:

The layer pads market is segmented based on material, number of walls, thickness, shape, distribution channel, and end user. Each segment contributes to the market’s overall growth by catering to specific needs:

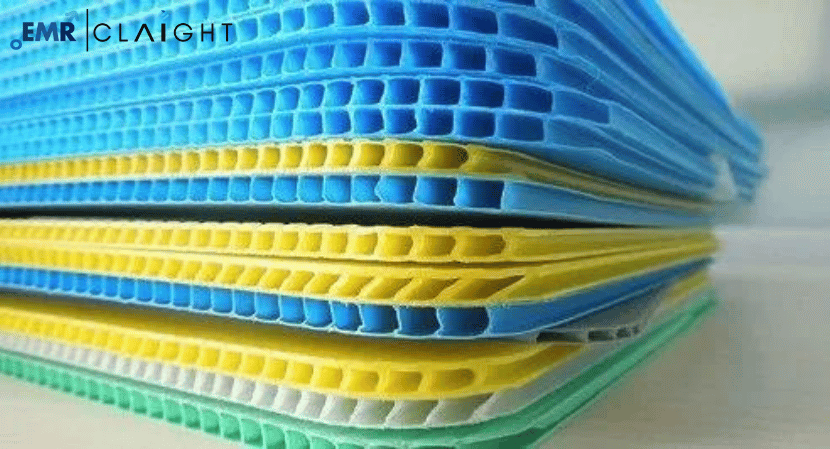

- Material: Plastic and paperboard are the primary materials used. Plastic is favored for its durability and moisture resistance, while paperboard is preferred for its eco-friendliness.

- Number of Walls: Single-walled, double-walled, and triple-walled layer pads offer varying levels of protection and strength, suitable for different weights and fragility levels of products.

- Thickness: Standard and customized thicknesses address different protection needs, allowing businesses to choose the most appropriate option for their products.

- Shape: Flat sheets and die-cut shapes provide versatility in packaging, with die-cut pads offering tailored solutions for irregularly shaped items.

- Distribution Channel: Online and offline stores, along with other bespoke channels, ensure that businesses can access layer pads conveniently and according to their purchasing preferences.

- End User: Industries such as food and agro products, beverages, electronics, chemicals, and others have distinct packaging needs that drive the demand for layer pads.

Layer Pads Market Trends and Drivers

- Expansion of Global Supply Chains:

- Cross-Border Trade: The globalization of supply chains and the rise in cross-border trade have amplified the need for reliable packaging materials. Layer pads are crucial in protecting goods during long-haul transportation and in diverse climatic conditions.

- Industrial Growth: Industries such as food and beverages, electronics, and chemicals continue to expand, driving the demand for effective packaging solutions like layer pads to ensure product integrity and safety.

- Rising Consumer Awareness:

- Product Safety: Consumers are increasingly aware of the importance of product safety during shipping. This awareness drives businesses to adopt high-quality packaging solutions, including layer pads, to prevent damage and maintain product quality.

- Sustainable Packaging Preferences: Consumers’ preference for sustainable packaging options is pushing companies to adopt eco-friendly materials, further boosting the demand for paperboard layer pads.

- Regulatory Pressures:

- Environmental Regulations: Stringent environmental regulations are compelling businesses to reduce their reliance on plastic packaging and shift towards recyclable and biodegradable alternatives. This regulatory push supports the growth of the paperboard layer pads segment.

- Packaging Standards: Adherence to international packaging standards and guidelines ensures the use of high-quality, protective materials like layer pads, fostering market growth.

- Economic Factors:

- Cost Efficiency: Layer pads contribute to cost efficiency by minimizing product damage and reducing returns. This cost-saving benefit is a significant driver for businesses seeking to optimize their packaging operations.

- Logistical Benefits: The use of layer pads improves stacking efficiency and stability, facilitating easier and safer handling of goods during storage and transportation.

Read More Reports:

Top 7 Companies Dominating the Global Digital Map Market Landscape

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com